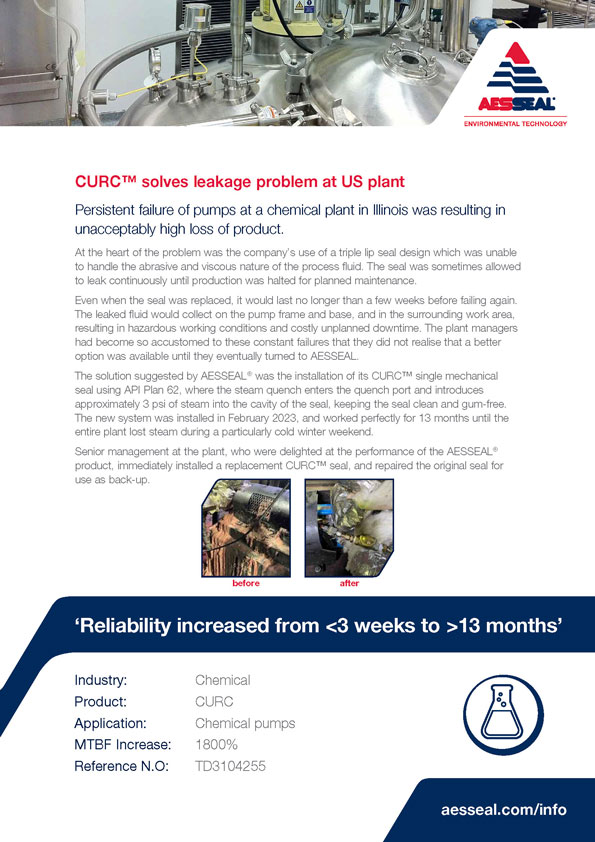

CURC solves leakage problem at US plant

Persistent failure of pumps at a chemical plant in Illinois was resulting in unacceptably high loss of product.

Click to Download

AESSEAL system fixes sewage problems for US township

A municipality in Pennsylvania was having issues with major inefficiencies in its sewage treatment system.

Click to Download

CURC the best option for US textile firm

Long lead times in procuring replacement parts for a large non-standard component seal were causing production delays for a US textile company.

Click to Download

AESSEAL cuts water usage by 75 percent at US company

A US mining company was concerned that its large end suction pumps were using excessive amounts of water.

Click to Download

AVT sensors save thousands for US company

Excessive vibrations in a vertical pump in a slurry pit application was leading to failure every month for the North Carolina company Befesa

Click to Download

Double seals solve reliability problem for US company

A New England pulp and paper company was reporting the persistent failure of its single seals

Click to Download

Improved reliability using dual seal and system

A corn wet milling plant in the USA had a problem with leaking seals on the centrifugal pumps.

Click to Download

Seal failures solved at US company

The installation of double cartridge mechanical seals and a water management system has solved a persistent and costly problem at a US paper mill.

Click to Download

LabTecta® FS the answer for gearbox problem

A repair and maintenance company in West Virginia says that its customers in the local coal mining industry have recorded major savings following a decision to upgrade to AESSEAL LabTecta FS.

Click to Download

LabTecta solves bearing problem

A US corn milling company was having a persistent problem with the failure of its dodge pillow block bearing.

Click to Download

DMSF seal the answer for US company

An oil seed producer in the US was reporting that in spite of trying a variety of possible solutions, single seals in the production process were only lasting a few months before failing.

Click to Download

AESSEAL seals the deal

A US oil seed producer was finding that the single seals used in the production process were inadequate, and were failing on average every three to six months.

Click to Download

AESSEAL lowers the temperature in Montana

A company in Montana was having trouble with an unreliable seal on a debutanizer reboiler pump. The problems were being caused by an inner seal cooler.

Click to Download

AESSEAL system eliminates danger of hydrogen sulfide release

A system installed at a US refinery has helped to eliminate a risk to personnel caused by the periodic release of hydrogen sulfide

Click to Download

Significant savings with new AESSEAL system

A corn milling company in the Midwest of the United States is in line to save hundreds of thousands of dollars.

Click to Download

Over a million US gallons of water saved

A Kentucky pulp and paper company is saving at least $19,000 a year following the replacement of its existing seals with AESSEAL products.

Click to Download

LabTecta seals solve leakage problems

A paper mill in the Northwest United States was experiencing persistent problems due to lubricant contamination in its refiners.

Click to Download

AESSEAL cures reliability issues at US wastewater facility

Damage to seals on the pumps at a large wastewater treatment plant in North Carolina was requiring regular and costly seal changes.

Click to Download

AESSEAL system aids clean-up at US feed mill

A US feed additives company reported loss of significant amounts of water due to leakage from double component seals.

Click to Download

LabTecta saving time and money at US plant

An oil seal, which had worn a deep fret mark in the output shaft of its Philadelphia Mixer Gearbox, which then leaked oil down through the worn-out mark.

Click to Download

Double seals bring major savings for Michigan firm

A Michigan paper company turned to AESSEAL looking to find a solution caused by an unpressurized packing pump, which allowed product to leak out of the system.

Click to Download

AESSEAL solves leakage problem at US paper mill

The installation of double cartridge mechanical seals and a water management system has solved a persistent leakage problem at a US paper mill.

Click to Download

Huge cost savings for US company with Magtecta unit

A US paper manufacturer has reported savings of more than $27,000 over just three years following the installation of an AESSEAL MagTecta™ unit.

Click to Download

New AESSEAL system brings major savings for US company

High levels of water consumption were causing growing concern at a US recycle paper mill. Water from the local public utility was being used as a flush on single seals at a rate of 720 gallons a day per pump, resulting in high water bills and a heavy cost from evaporation.

Click to Download

Lower costs and greater reliability for US pharma company

Frequent seal changes and heavy water use were causing operational problems and rising costs for a US pharmaceutical company.

Click to Download

Price and lead time more than halved

A seal failure at a US corn milling company resulted in 12 weeks of downtime when the new cartridge seal supplied by one of AESSEAL’s competitors turned out to be the wrong specification.

Click to Download

AESSEAL helps significantly reduce downtime

A US corn milling and food additives company was reporting problems resulting from incorrectly cut bulk packing.

Click to Download

Cartridge seal simplifies maintenance and improves reliability

Pump repair specialist, Production Pump in the USA were looking to improve pump reliability in the Oil and Gas Industry.

Click to Download

Seal upgrade improves reliability and saves over US$81k

A major oil and gas customer in Oman was experiencing continuous leakage from the gland packing used on their export booster pumps.

Click to Download

MagTecta improves gearbox reliability

A gas processing facility in the USA was experiencing water ingress and oil leakage into one of its gearboxes.

Click to Download

Lip seal upgrade for US petrochemical plant

A petrochemical plant in the USA was experiencing problems with oil leaking from the vertical input shafts of their pumps and called upon AESSEAL to help out with a solution.

Click to Download

Reduce maintenance costs with reliability upgrade

A specialty chemical company in the USA were dissatisfied with the reliability of 6 water pumps.

Click to Download

MagTecta improves cooling tower fan reliability

A gas processing facility in the USA were having constant problems with the bearings on their cooling tower fans.

Click to Download

AES-Elast™ successfully replaces leading brand

A leading global chemical company uses AES-Elast in their Terephthalic Acid (T.P.A) processing facility to seal acetic acid applications.

Click to Download

Efficient seal support system reduces energy costs

A chemicals manufacturer in the USA was concerned about high energy associated with the sealing of a hot glycol pump.

Click to Download

Vertical reactor on PVC reactor - $19,000 savings and swift ROI

A petrochemical company in Kentucky, USA, was using a competitor’s reactor seal on a vertical reactor containing PVC slurry.

Click to Download

Specialty Chemical Company achieves improved reliability

A specialty chemicals manufacturer in the USA was experiencing ongoing reliability issues with the top mounted dual mixer seal on a vessel mixing silicone oil.

Click to Download

MagTecta eliminates gearbox oil leakage

Twin Rivers Paper at its Maine USA plant were dissatisfied with the sealing arrangement on the gear boxes that are the main drive for the paper machine rolls.

Click to Download

Success with bad actor pump leads to further opportunity

A pulp mill in the USA were experiencing issues with the sealing arrangement on the green liquor transfer pumps.

Click to Download

LabTecta reduces quality issues and improves reliability

A paper manufacturer in the USA was experiencing oil leakage from the journals in the dryer section of its paper machine.

Click to Download

LabTecta eliminates oil leakage

A paper company in the USA was experiencing problems with oil leakage around the lip seals on its ‘Fluffer’.

Click to Download

9+ Years MTBF for condensate pump

USA Paper producer found mechanical seals used on condensate applications had an unacceptable Mean Time Between Failure.

Click to Download

AESSEAL SW system solves water pressure problem

A US paper company to use the advantages provided by the SW Seal Water Management systems.

Click to Download

Change to AESSEAL helps reduce filter downtime

Pulp and paper company has now gone more than 12 months without replacing a seal.

Click to Download

New seal design the difference at US firm

Reliability problems leading to significant downtime and high maintenance costs at pulp and paper company.

Click to Download

The AESSEAL DMSF helps cut water usage for US company

DMSF™ mechanical seal and system has helped to reduce water usage and maintenance costs.

Click to Download

Annual savings of over $2.6 million

A food and beverage customer was experiencing high leakage and contamination in their process fluid on the single pass flow through system they were operating.

Click to Download

Reliability upgrade saves $24k per year

A speciality chemical company in the USA was experiencing problems with the mechanical seal fitted on a venturi scrubber.

Click to Download

Solution delivers $17,000 inventory cost savings

ADM was dealing with a range of problems due to lack of standardisation on the pump sealing systems corn milling plants in Nebraska.

Click to Download

Reliability upgrade improves MTBF 2900%

A speciality chemical company in the USA was experiencing problems with the mechanical seal fitted on a phenol pump.

Click to Download

Gas seal gives 11 years trouble free operation

Eastman Chemicals’ Kingsport Tennessee production plant were experiencing problems with leakage of the mechanical seals on their Xylene pumps.

Click to Download

Reliability upgrade eliminates unscheduled downtime

An oil refinery in the USA was experiencing excessive seal failures with some even leaking straight from start up.

Click to Download

Massive water savings with improved reliability

A Bio Products manufacturer was concerned about the water used by the sealing systems at one of its manufacturing facility in the USA.

Click to Download

Reduced downtime, improved safety

Using gland packing to seal an Armstrong – Chemtec crystalliser.

Click to Download

Successful Support System Upgrade Improves Plant Reliability

A chemicals manufacturer in the USA was experiencing ongoing issues with the reliability of the seal support system supplying a double seal.

Click to Download

Unique solution saves $287,000 a year and improves safety

One of the world’s largest nutrition companies was dealing with repeated downtime due to problems with clean condensate pump seals on a corn wet milling application at its plant in Illinois, USA.

Click to Download

Reliability upgrade reduces seal repair costs

Carbon Free are a chemical company who are developing patented technologies that capture CO2 from stationary point emitters and transform them into carbon negative chemicals.

Click to Download

Chemical company saves over $225,000 in first year

Eastman Chemicals Kingsport Tennessee production plant were experiencing problems with leakage of the mechanical seals on their cellulose esters pumps.

Click to Download

Seal upgrade saves cornmill $280,000 in repairs and downtime

Cargill Corn Milling Inc was experiencing leakage on the seals of a boiler feed pump at its plant in Iowa, USA.

Click to Download

Upgrade delivers annual saving of 15,000 USD

ADM, which produces high quality renewable chemicals for a range of industries, had experienced repeated seal failure on a Goulds Pump 3196 MTX pump at its plant in North Carolina, USA.

Click to Download

MTBF increases by 233%

Seadrift Coke L.P., a Texas based stand-alone coker, was experiencing repeat seal failures on a hot oil pump, leading to unscheduled downtime every six months.

Click to Download

Reduced downtime and health & safety benefits

Cargill Corn Milling Inc was concerned about reduced operational efficiency, the risk of contamination and workforce safety due to ongoing leakage from a fibre press at its Nebraska plant.

Click to Download

Improved safety and production efficiency while reducing water consumption

The slurry tailing pumps at a potash mine were experiencing bearing failure due to ingress of tailings into the bearing frames. The pumps were sealed with Gland Packing and flushed with water. In addition to bearing damage, large volumes of water around the pump were giving safety concerns.

Click to Download

Paper producer saves more than one million Dollars per year

A leading North American producer of Pulp and Paper recognise the importance of operating their business in a sustainable way.

Click to Download

LabTecta upgrade gives over 12 years of trouble free operation

A paper mill in Maine, USA was having issues with water and stock getting into their Hydropulper gearbox.

Click to Download

Eliminating a $225,000 maintenance bill

A leading food processor was experiencing problems sealing two Nash Vacuum pumps

Click to Download

$40,000 a year saving with LabTecta

Eliminating steam ingress into the pillow block bearings on a primary air fan, significantly reducing bearing failure.

Click to Download

Reduced pump failure delivered over $11,000 cost saving in first year of operation

Chemical manufacturer had seven seal failures in a year

Click to Download

Upgrading unreliable seals increases MTBF from 2-3 months to 3 years

Pulp and Paper industry increases plant reliability and reduces maintenance costs.

Click to Download

$10,500 yearly cost saving for Chemical manufacturer

Eliminating oil leakage from a boiler feed pump with a LabTecta-PB™ that is specifically designed for sealing split bearing blocks.

Click to Download